Oil heaters – solutions for the industrial sector

Heating processes for liquids oil

The variety of solutions for heating oil is in no way inferior to that of water heating. As a general rule, oil heaters require a comparatively larger heat exchange surface, since the surface load capacity of oils is much lower. The quality of the plant depends greatly on the specification of appropriate surface load for the particular oil and its flow rate: If the film temperature is too high, the oil will crack on the heater. Break-offs in the flow should also be taken into account during design and construction.

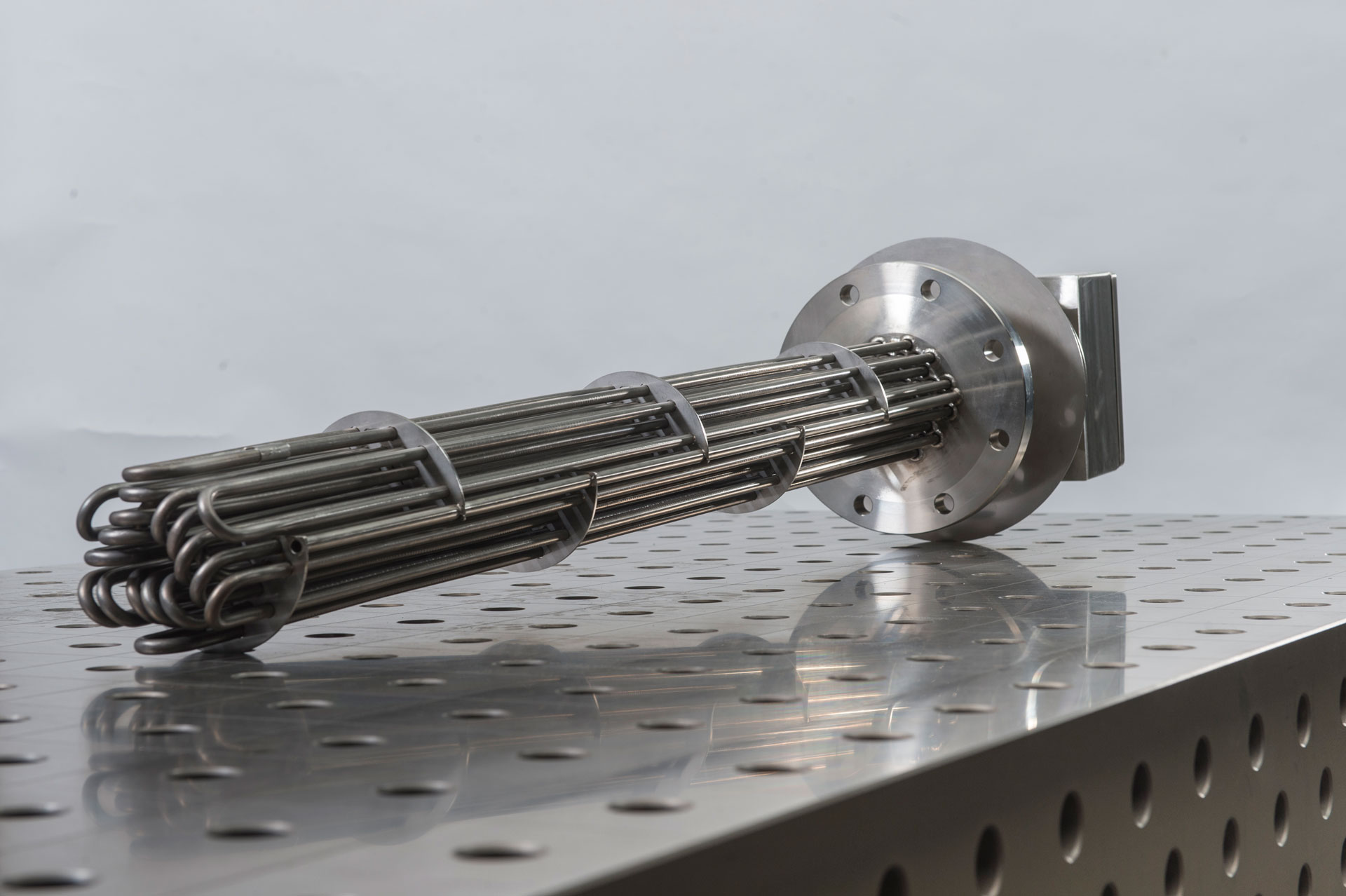

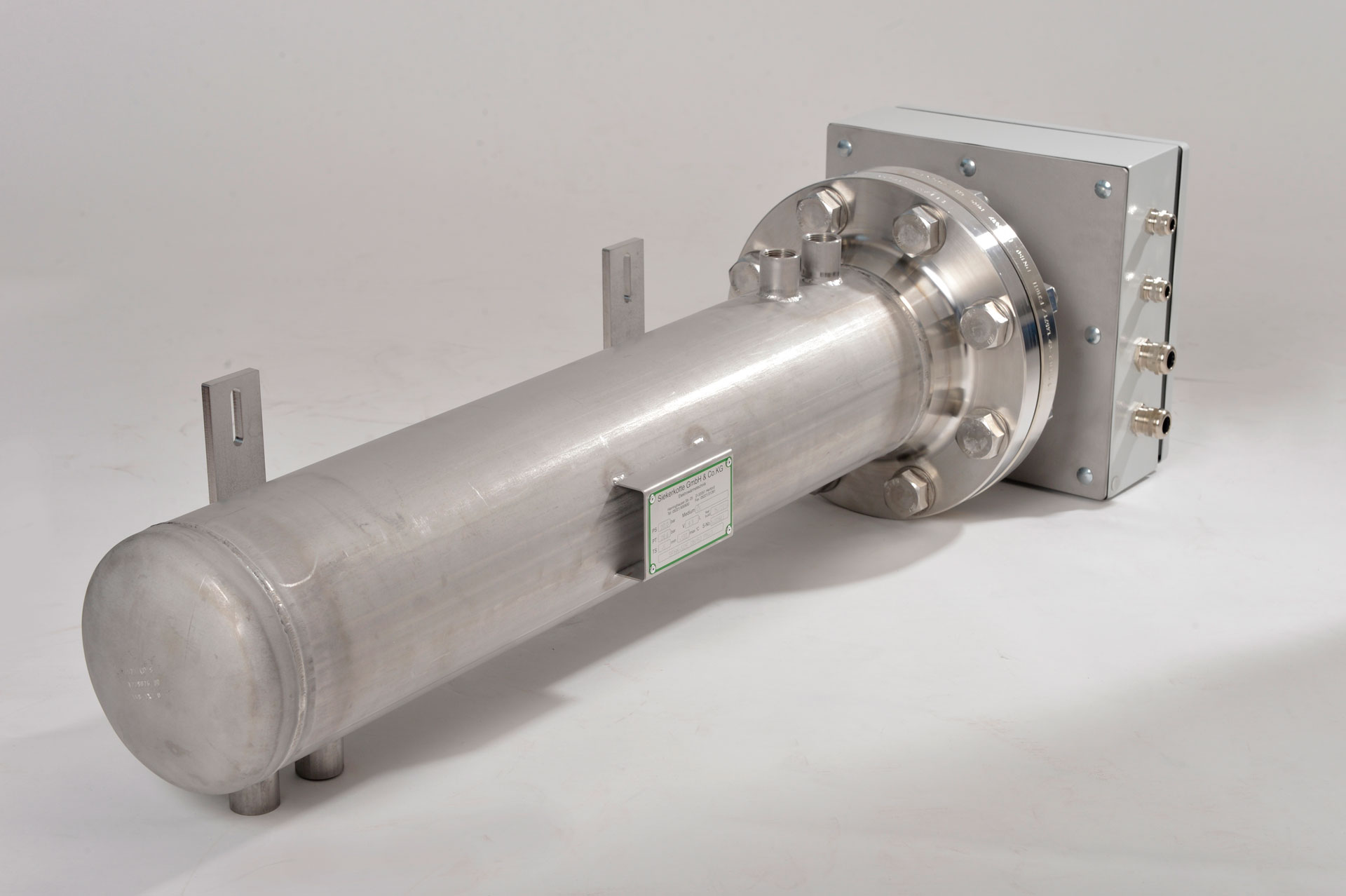

As a replaceable solution for oil tanks, Siekerkotte offers its customers cartridge heaters whose tubes are screwed in or flanged to the tank. The heat source consists of a ceramic heater, a tubular heater or a high density cartridge heater in the tube(s), which can be replaced without draining the oil. But long-term stable solutions are also possible with conventional screw-in or flanged heaters, including as continuous tankless water heaters based on tubular heaters.

- Viscosity

- Surface load

- Cracks

- Material quality