Air heater

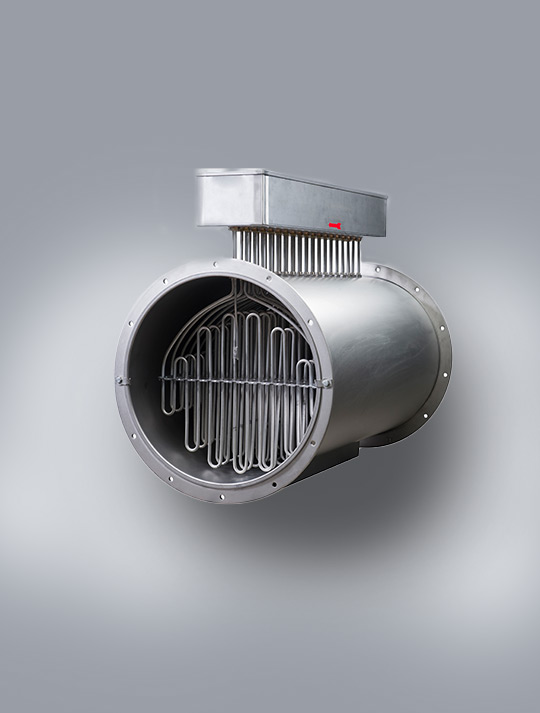

SERL/SEKL

Industrial process technologies often require electric air heaters, such as in air conditioning and process engineering or industrial furnace and drying plant construction. In addition to reduced emissions, electric heaters are characterized by their high thermal efficiency and low maintenance requirements. Depending on the existing or desired system design, they are designed as SEKL rectangular duct air heaters, SERL tubular air heaters, SEFL flanged air heaters or, for increased system pressure, as classic SDE tankless water heaters.

High thermal efficiency and compact design

Wide range of connection designs (rectangular duct, tubular, continuous, flanged air heaters)

Flow-optimized design with low pressure losses

Ready-to-connect, mobile or skid solutions incl. fans, insulation, rollers etc. available on request.

Individual control (thyristor/contactor controls) and monitoring of processes

Application areas for air heaters

- Air

- Industrial gases (nitrogen, carbon dioxide, flue gas, hydrogen, etc.)

- Air conditionning technology, industrial furnace construction, drying technology

- Exhaust air purification, catalytic afterburning

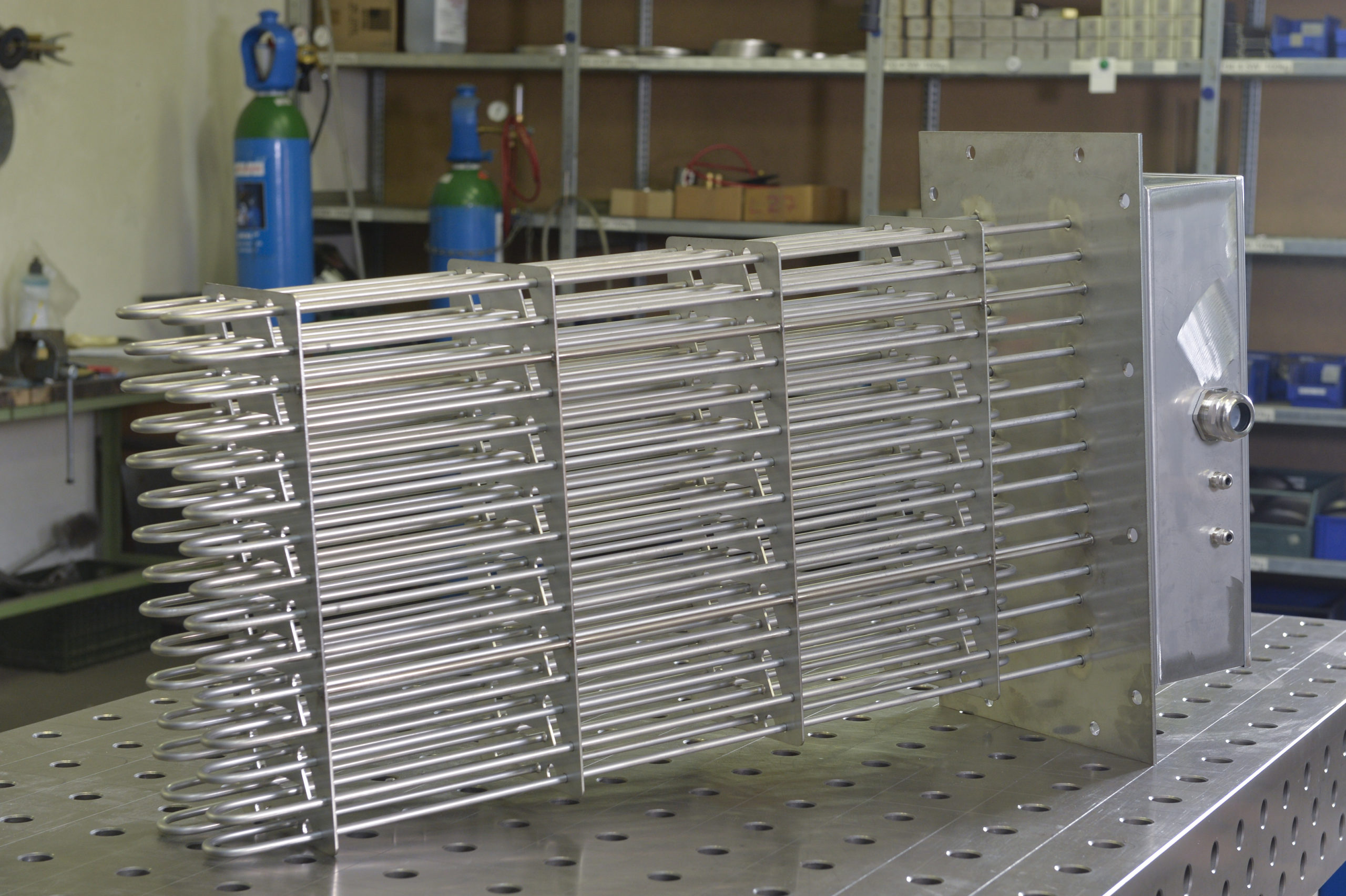

Structure and material

Process-specific engineering optimizes flow velocity and surface loading of tubular heaters while minimizing pressure drop. During operation, the temperature of heaters and medium is monitored to prevent overheating in the event of a stall. Various temperature limiters and controllers, measuring sensors such as wind vane relays, as well as thyristor and contactor controls are available for this purpose.

Housings are made of stainless steel with a degree of protection up to IP69. Tubular heaters with diameters of 8.5mm, 10.0mm, 11.5mm or 16.0mm are used as the heat source, the materials of which are selected according to the corrosiveness and temperature of the medium.

We offer constructions including fans, insulation, rollers, etc., for mobile setups or skid solutions upon request. We specify and manufacture our products according to international standards (DGRL 97/23/EG, AD2000, EN 13455, ASME), as well as acceptance by TÜV/ DNV etc. if required.

Housings are made of stainless steel with a degree of protection up to IP69. Tubular heaters with diameters of 8.5mm, 10.0mm, 11.5mm or 16.0mm are used as the heat source, the materials of which are selected according to the corrosiveness and temperature of the medium.

We offer constructions including fans, insulation, rollers, etc., for mobile setups or skid solutions upon request. We specify and manufacture our products according to international standards (DGRL 97/23/EG, AD2000, EN 13455, ASME), as well as acceptance by TÜV/ DNV etc. if required.

Technical data

Tubular heater

Diameter

8.5 mm; 11.5 mm; 16 mm

Material

1.4571; 1.4828; 1.4876; 2.4858

Immersion depth/pipe diameter/duct cross section

150 mm - 2500 mm

Unheated length

By agreement

Design variants

Dimensions

Duct air heater – DIN 24 158, page 3, line 3

Tubular air heater – DIN or Jacob pipe; DN50..DN630

Flange heater, flange

Material

1.4301; 1.4571; 1.4828

IP protection class

IP protection class

IP43 to IP66

Control / monitoring

Mechanical or electronic temperature controllers and/or limiters

By agreement

Thyristor or contactor controls

By agreement

Wind vane relay

By agreement

Options

Fan

Mobile or skid mounted

Let’s talk about it!

No electric heating solution is exactly like the other! Let us advise you on what your optimal heating solution looks like.

Write an email