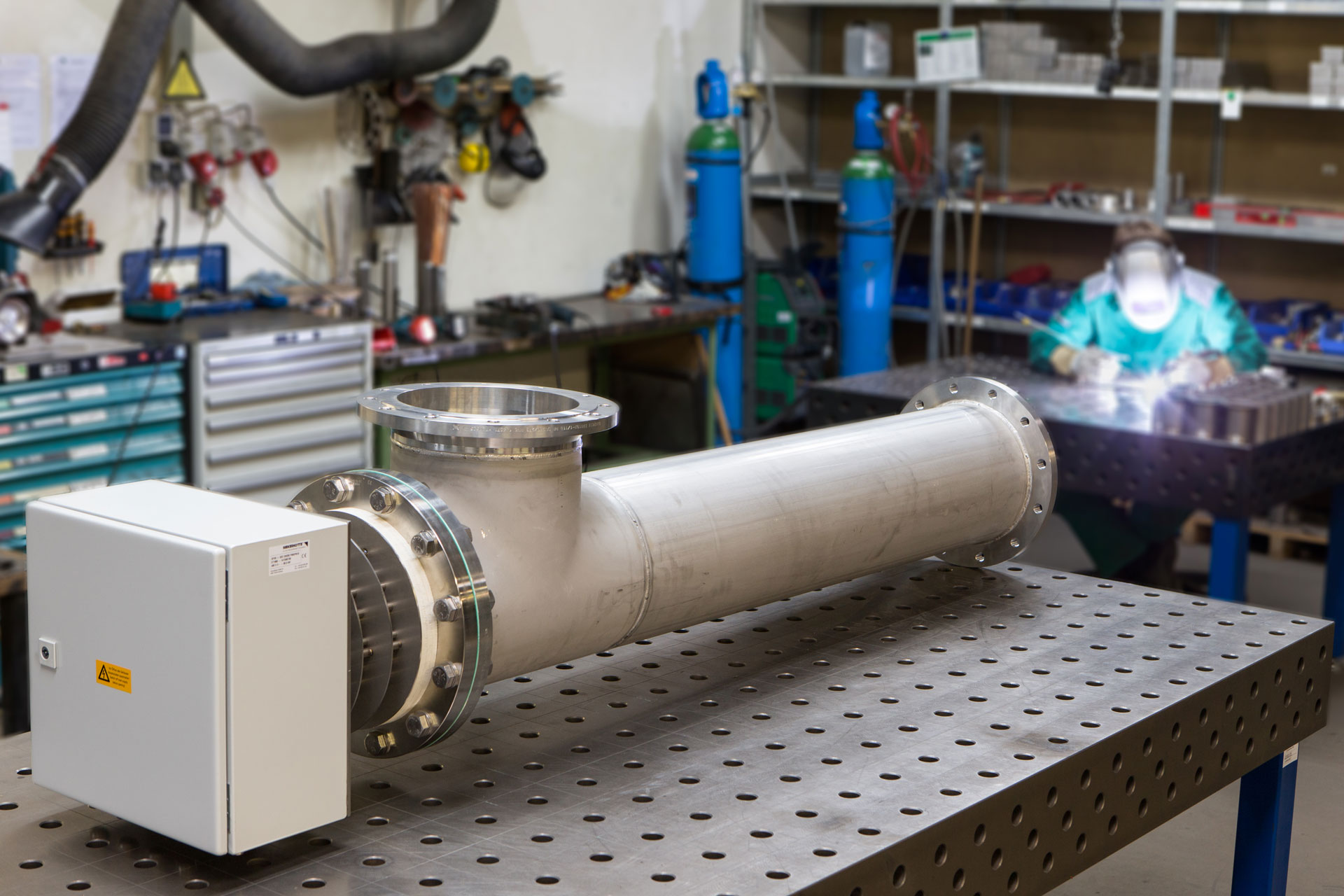

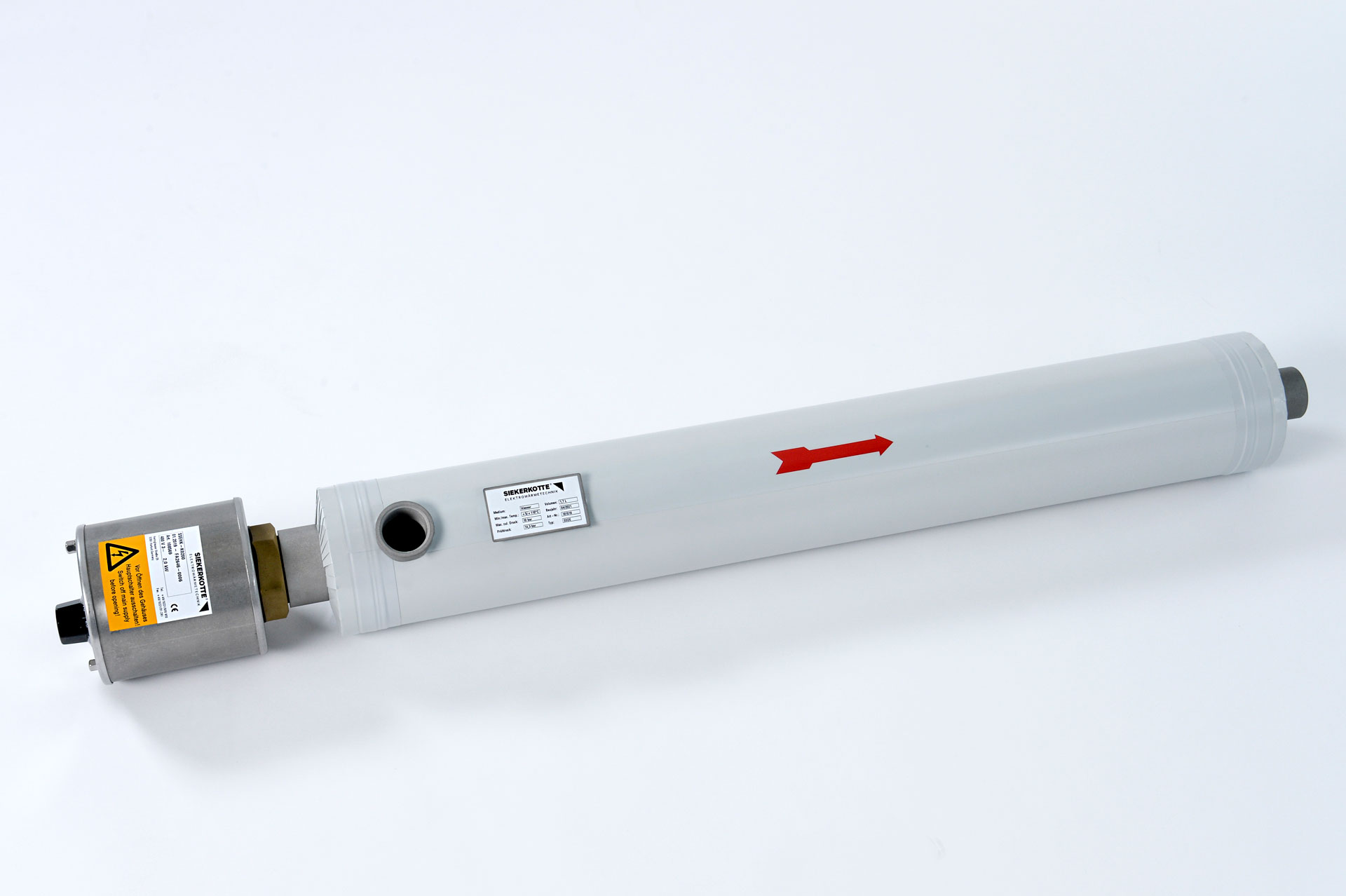

SDE tankless water heater

Industrial electric tankless water heaters are made of a screw-in or flanged heater and a matching flow tube. The design of these heaters is adapted to the process conditions ; decisive parameters being the medium to be heated, flow velocity, desired temperature increase and process pressure. On request, we supply tankless water heaters with a suitable control system, insulation, expansion tank, etc.

Flow-optimized design with low pressure losses

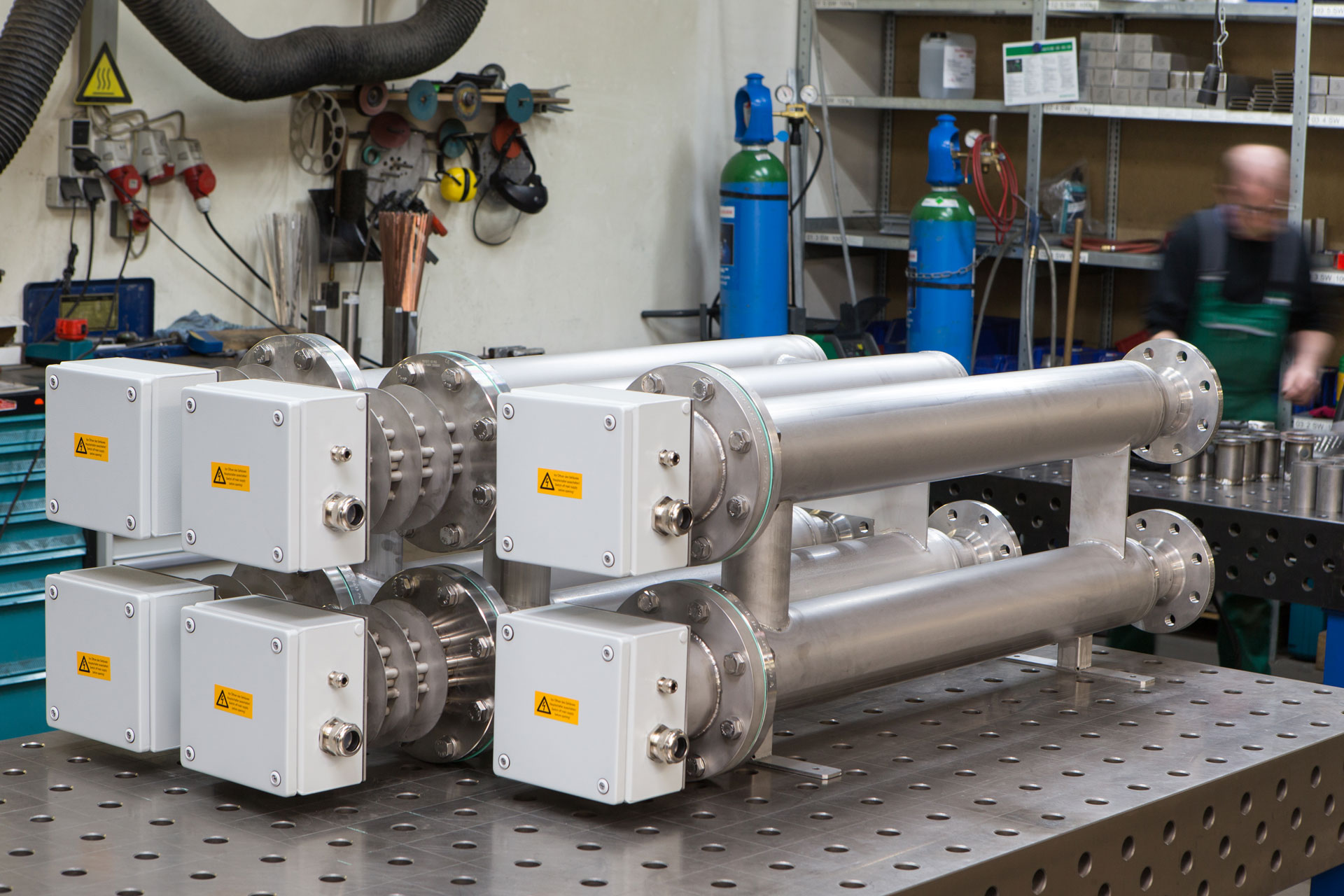

Also available as a multi-stage cascade solution for increased power requirements

Customized connection sleeves/flanges, ready-made skid solutions incl. pumps, valves, insulation, etc. available on request

Reference solutions for tankless water heaters up to 10MW available

Individual control (thyristor/contactor controls) and monitoring of processes

Items available in the shop now

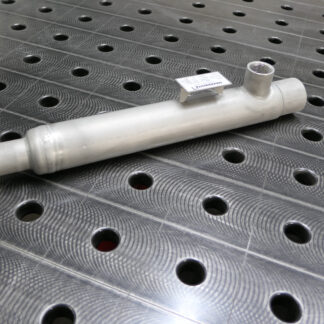

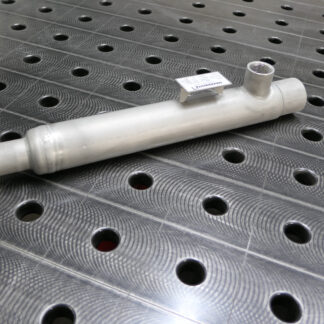

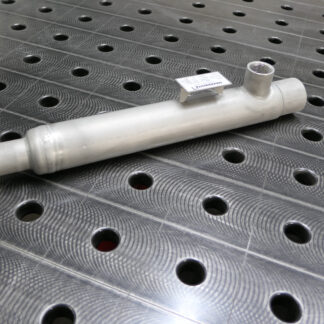

181012

Durchlaufrohr für Einschraubheizkörper SEHK 2,0 & 3,0 kW

- für SEHK Einbautiefe 275 mm

- passend f. Art.Nr. 181000/ 181001/ 181007

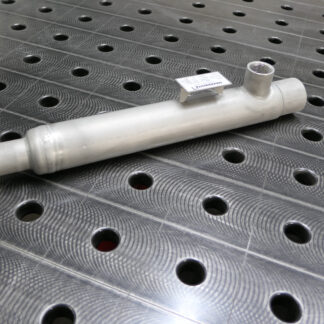

181015

Durchlaufrohr für Einschraubheizkörper SEHK 7,5 kW

- für SEHK Einbautiefe 605 mm

- passend f. Art.Nr. 181004/ 181010

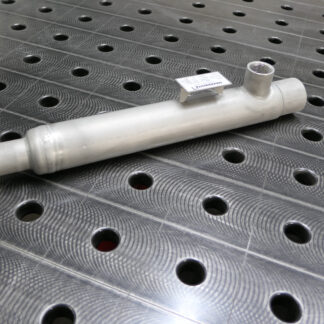

181013

Durchlaufrohr für Einschraubheizkörper SEHK 4,5 kW

- für SEHK Einbautiefe 395 mm

- passend f. Art.Nr. 181002/ 181008

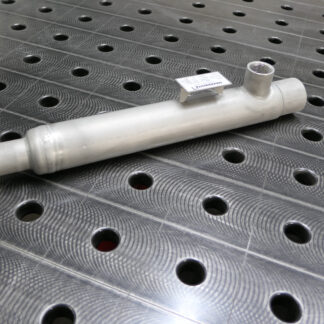

181014

Durchlaufrohr für Einschraubheizkörper SEHK 6,0 kW

- für SEHK Einbautiefe 500 mm

- passend f. Art.Nr. 181003/ 181009

181016

Durchlaufrohr für Einschraubheizkörper SEHK 9,0 kW

- für SEHK Einbautiefe 710 mm

- passend f. Art.Nr. 181005/ 181011

181017

Durchlaufrohr für Einschraubheizkörper SEHK 12,0 kW

- für SEHK Einbautiefe 920 mm

- passend f. Art.Nr. 181006

Application areas for tankless water heaters

- Drinking water, circulating water, deionized water, demineralized water, WFI, pharmaceutical water, etc.

- Lubricating oil, hydraulic oil, heat transfer oil, canola oil, palm oil, heavy oil, bitumen, etc.

- Air, nitrogen, carbon dioxide, hydrogen, flue gas, etc.

- Steam, saturated steam

- Power2Heat / power-to-heat applications

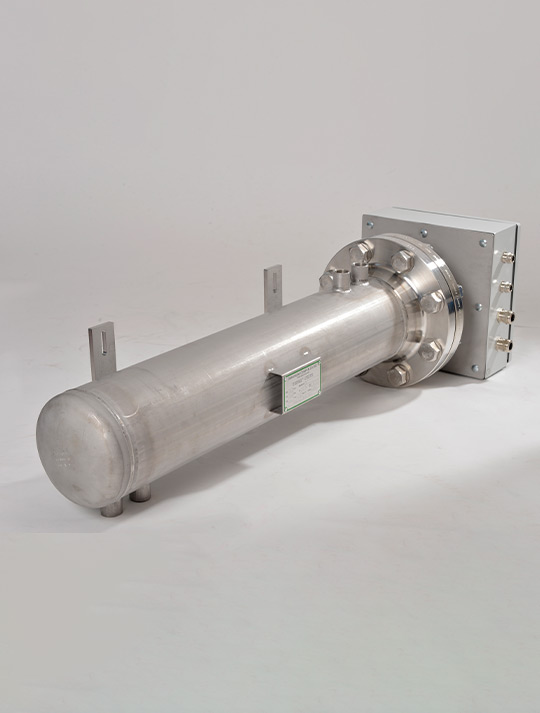

Structure and material

Industrial electric SDE tankless water heaters are made from high density tubular heaters that are welded/brazed into a blind flange or screw head and which heat the medium in a flow/pressure vessel. Dimensions, outflow and inflow as well as performance are constructed and designed according to customer requirements. Multi-stage cascades or skids can be realized and supplied for larger power requirements.

Process-optimized and modular systems allow the SDE to perfectly match the customer’s heating requirements. Blind flanges and flow tubes can be supplied in different CrNi steels (1.4301, 1.4541, 1.4571, 2.4858), flanges up to DN1200 diameter are possible. Customers can select connection spigots/sleeves according to their requirements, and all elements meet protection classes up to IP69.

Reference solutions in the MW range for power-to-heat solutions are available.

In addition to the usual temperature controllers and limiters, Siekerkotte offers optional level monitoring of the medium to prevent heating elements from burning out.

These units are shipped fully assembled and electrically wired and can be installed on site if required.

Particular attention should be paid to regulating tankless water heaters. Depending on the application and any existing ICE concept, Siekerkotte offers individual thyristor and contactor control systems as well as complete automation solutions.

Process-optimized and modular systems allow the SDE to perfectly match the customer’s heating requirements. Blind flanges and flow tubes can be supplied in different CrNi steels (1.4301, 1.4541, 1.4571, 2.4858), flanges up to DN1200 diameter are possible. Customers can select connection spigots/sleeves according to their requirements, and all elements meet protection classes up to IP69.

Reference solutions in the MW range for power-to-heat solutions are available.

In addition to the usual temperature controllers and limiters, Siekerkotte offers optional level monitoring of the medium to prevent heating elements from burning out.

These units are shipped fully assembled and electrically wired and can be installed on site if required.

Particular attention should be paid to regulating tankless water heaters. Depending on the application and any existing ICE concept, Siekerkotte offers individual thyristor and contactor control systems as well as complete automation solutions.

Technical data

Tubular heater

Diameter

6.5 mm; 8.5 mm; 10.0 mm; 11.5 mm; 16.0 mm

Material

1.4404; 1.4571; 1.4828; 1.4876; 2.4858

Immersion depth

150 mm - 3000 mm

Flange

Design

DIN; tri-clamp; ASME; special flange, sleeves/threaded nipples

Diameter

By agreement

Pressure level

By agreement

Material

Steel (pressure vessel plate H II); 1.4301; 1.4404; 1.4539; 1.4541; 1.4571;

Flow tube

Design

Single or cascade design

Material

Steel painted; 1.4301; 1.4541; 1.4571

IP protection class

IP protection class

IP43 to IP69

Control / monitoring

Temperature sensor

PT100; sheath thermocouples; capillary tube thermostats

Thyristor or contactor controls

By agreement

Flow monitor

By agreement

Options

Cascade design

Baffles

Complete solutions incl. pumps, valves, expansion tanks, etc.

Insulation, etc.

Let’s talk about it!

No electric heating solution is exactly like the other! Let us advise you on what your optimal heating solution looks like.

Write an email