Warm Up – clear and simple explanation of technical terms

Each subject area has its own terminology, technical terms and linguistic concepts. What one person considers a screw-in heater can be an immersion heater to another, or even simply a heater. You will learn what this means for the field of electric heat and why, for example, surface load is one of the most important issues and what effect it has on your heating process and the life of the heater.

Beschreibung der Fachbegriffe

Electric screw-in heater

Electric tubular heater

Electric tankless water heater

Surface load

Joule’s first law

Ohm’s law

Series connection

Parallel connection

Electric power

Film temperature

Heat transfer

Thermal capacity

Heat conduction

Convection

Thermal radiation

Three-phase system

Low dead space

Electric flange heater

Electric screw-in heater

Refers to an electric heater that is screwed into a tank by a screw head in order to bring the medium inside to the required temperature. Siekerkotte manufactures countless variants with a wide variety of output sizes, materials, screw heads and tubular heaters. For heating water, Siekerkotte has standard electric screw-in heaters in stock and offers a delivery time of 48 hours.

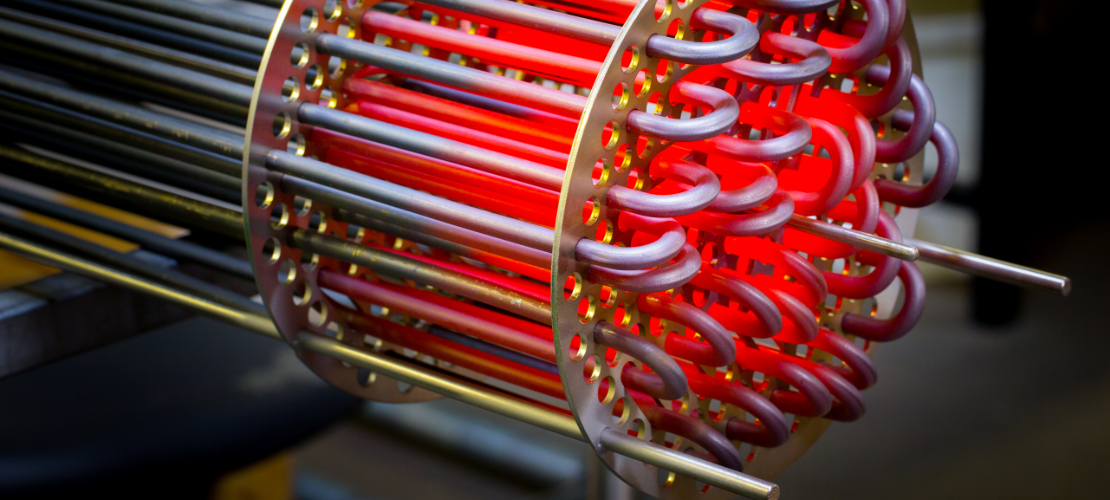

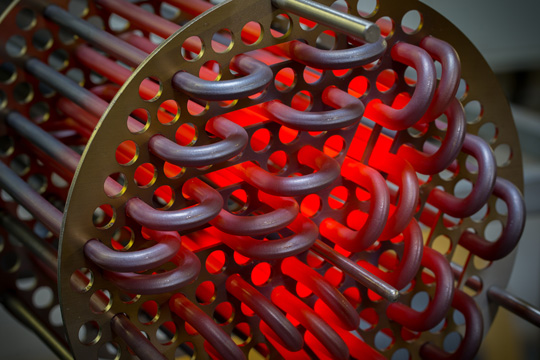

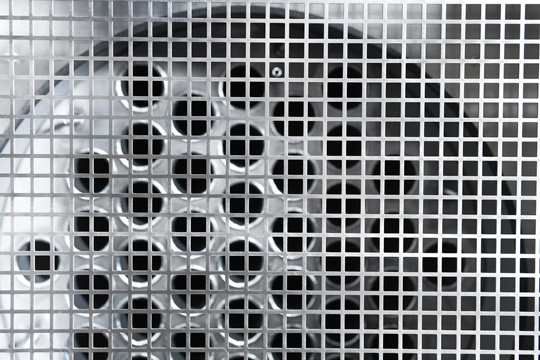

Electric tubular heater

These form the heart of almost all our electric heaters. Tubular heaters consist of stainless steel tubes, in the center of which an electric heating wire is inserted. Its ohmic resistance defines its electrical heating power. This heating wire is encased in magnesium oxide, which electrically separates the current-carrying wire from the metallic outer body. Magnesium oxide is an extremely good heat conductor: heat generated in the heating wire is transferred to the outer sheath in contact with the medium with virtually no loss. Siekerkotte offers tubular heaters in different lengths and shapes with diameters of 6.5, 8.5, 10, 11.5 as well as 16 mm.

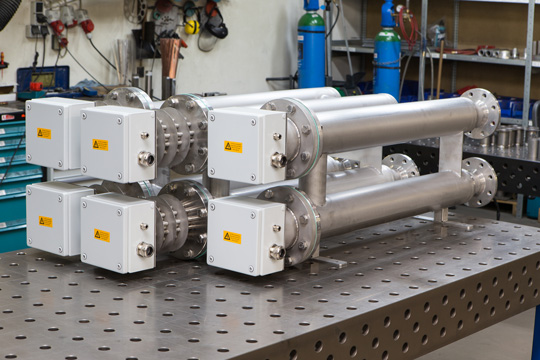

Electric tankless water heater

Refers to an electric heater which, in addition to the heating element – usually an electric flange heater – also has a flow tube through which the medium to be heated flows. Tankless water heaters can be connected to the customer’s piping system by connection flanges or sleeves. If there is an overpressure of more than 0.5 bar in the system, the tankless water heater must be designed and produced in accordance with the Pressure Equipment Directive. Siekerkotte offers electric tankless water heaters up to the megawatt range for a wide variety of media and pressure levels.

Surface load

The most important parameter for dimensioning electric heating elements is the surface load, often also referred to as “area-related power”. It is an important measure of the stress and service life of a heating element. The surface load is expressed in watts per cm². It is calculated according to the following formula: Surface load is the power (P) divided by the heated surface area of the tubular heater (so in this case, the shell area of a cylinder): Surface load = P/ (2πrh) [W/cm²].

It should be noted that the unheated length of the tubular heater must be subtracted from the height h.

The maximum permissible surface load differs for each medium; the medium can only absorb limited thermal energy depending on its own heat capacity. The following limits (max. guide values) should not be exceeded:

Air: 4 W/cm²

Water: 10 W/cm²

Oils: 2 W/cm²

It should be noted that the unheated length of the tubular heater must be subtracted from the height h.

The maximum permissible surface load differs for each medium; the medium can only absorb limited thermal energy depending on its own heat capacity. The following limits (max. guide values) should not be exceeded:

Air: 4 W/cm²

Water: 10 W/cm²

Oils: 2 W/cm²

Joule’s first law

Also called simply Joule’s law. It states that an electric current in an electrical conductor generates heat energy by continuously transforming electrical energy drawn from the conductor. The applicable formula is Q = P x t. You feel the same effect when you use your cell phone for a longer period of time. The back of the cell phone gets warm because the battery emits electricity.

Ohm’s law

Ohm’s law (or more precisely, Ohm's rule) states that the strength of the electric current flowing through an object is proportional to the applied electric voltage. The applicable formula is U = R x I. With known voltage and current, it is quite easy to calculate electrical resistance R [Ohm].

Series connection

When several electrical resistors are connected in series, the total resistance Rg=R1 + R2 + R3 + ... Rn is a simple addition of all individual resistors. It should be noted that the current I flowing through all resistors remains the same.

Parallel connection

When different resistors are arranged in parallel, the reciprocal values (also called conductance S = 1/R [Siemens]) are added. 1/Rg= 1/R1+ 1/R2+ 1/R3+ … + 1/Rn. When only two resistors are connected in parallel, the formula for calculating total resistance is simplified: Rg= R1 R2 /(R1 + R2). Voltage across each resistor connected in parallel remains the same; individual currents flowing through each resistor add up to the total current. It can be said that the current conductivity of the overall system increases with each additional resistor connected in parallel.

Electric power

For direct current, electric power P is calculated from the product of the voltage U and the current I: P = U x I [W]. Using Ohm’s law, the formula can be rewritten as follows: P = U x I = U² / R = R x I².

If an alternating current or alternating voltage is present, then the cosine of the phase angle ϕ must also be included in the product when calculating active electric power. Pact = U x I x cos ϕ.

If an alternating current or alternating voltage is present, then the cosine of the phase angle ϕ must also be included in the product when calculating active electric power. Pact = U x I x cos ϕ.

Film temperature

In the field of heating heat transfer oils in particular, film temperature plays an important role. Liquids move significantly less when directly at the boundary layer between the medium to be heated and the hot surface of tubular heaters than further away from it. The medium can only pass on absorbed thermal energy in the form of heat conduction. To prevent cracking and the resulting formation of deposits on the tubular heaters, it is important not to exceed the maximum permissible film temperature. This is regulated in the standard DIN 4754. For mineral heat transfer oils, these values lie between 260 and 350 °C, for synthetic oils up to 430 °C, and for water usually between 150 and 180 °C.

Heat transfer

To transfer thermal energy further, there are three different possibilities, which all occur mostly parallel to each other in nature: Heat conduction, convection and radiation. In the case of electric heaters for liquid media, we mainly use heat conduction and convection. In the case of air and gas heaters, heat radiation can also be used for energy transfer.

Thermal capacity

The thermal capacity C of a body represents the ratio of the heat supplied to it to the temperature increase (ΔT) caused by it. The thermal capacity of homogeneous bodies can be calculated as the product of its molar heat capacity and its amount of substance. Both values can be found in corresponding technical lists.

Heat conduction

Heat conduction involves the transportation of heat in solid,

liquid and gaseous media under the influence of the temperature difference. Energy is transferred in the molecular bond by vibrations; there is a physical contact. Heat is transported in the direction of decreasing temperature. The greater the temperature difference as well as the thermal conductivity of the medium, the stronger the heat. This also influences the speed of heat conduction.

liquid and gaseous media under the influence of the temperature difference. Energy is transferred in the molecular bond by vibrations; there is a physical contact. Heat is transported in the direction of decreasing temperature. The greater the temperature difference as well as the thermal conductivity of the medium, the stronger the heat. This also influences the speed of heat conduction.

Convection

In heat convection, heat is transported by gas or fluid flows created by local heating or temperature differences. This means that the kinetic energy of the gas molecules is increased. Energy is transported on a molecular level.

Thermal radiation

Thermal radiation is the transfer of energy by electromagnetic waves. These can be of different frequency or wavelength. Every warm body emits electromagnetic waves that are on the infrared part of the spectrum, i.e. have a relatively long wavelength. At high temperatures, thermal radiation becomes visible and its energy increases sharply, but it is also quite significant at low temperatures.

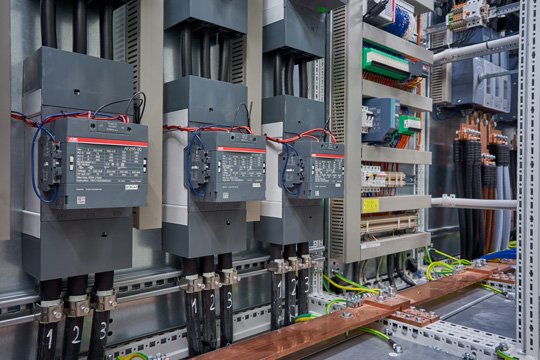

Three-phase system

A three-phase system is defined as a system consisting of three individual alternating currents or alternating voltages of the same frequency, whose phase angles are permanently shifted by 120° with respect to each other. The three-phase system is used primarily in the field of electrical power engineering for the transport and distribution of electrical energy in power grids. Typically, the voltage level used is 400 volts.

Low dead space

In pharmaceutical and highly sterile applications, it is crucial to avoid “dead spaces”, i.e. areas in which the medium is stationary and not properly mixed due to lack of flow, as contamination can occur here. Siekerkotte offers low dead space heaters for highly sterile applications such as WFI. Our heaters are rolled and electropolished to meet most hygiene requirements.

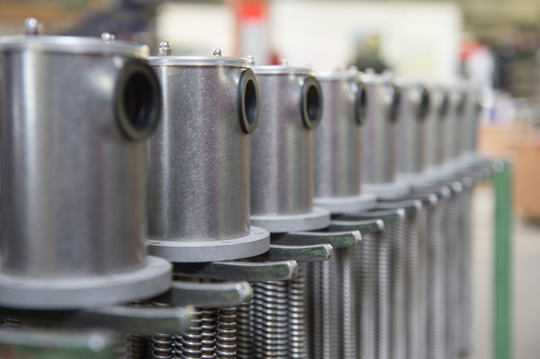

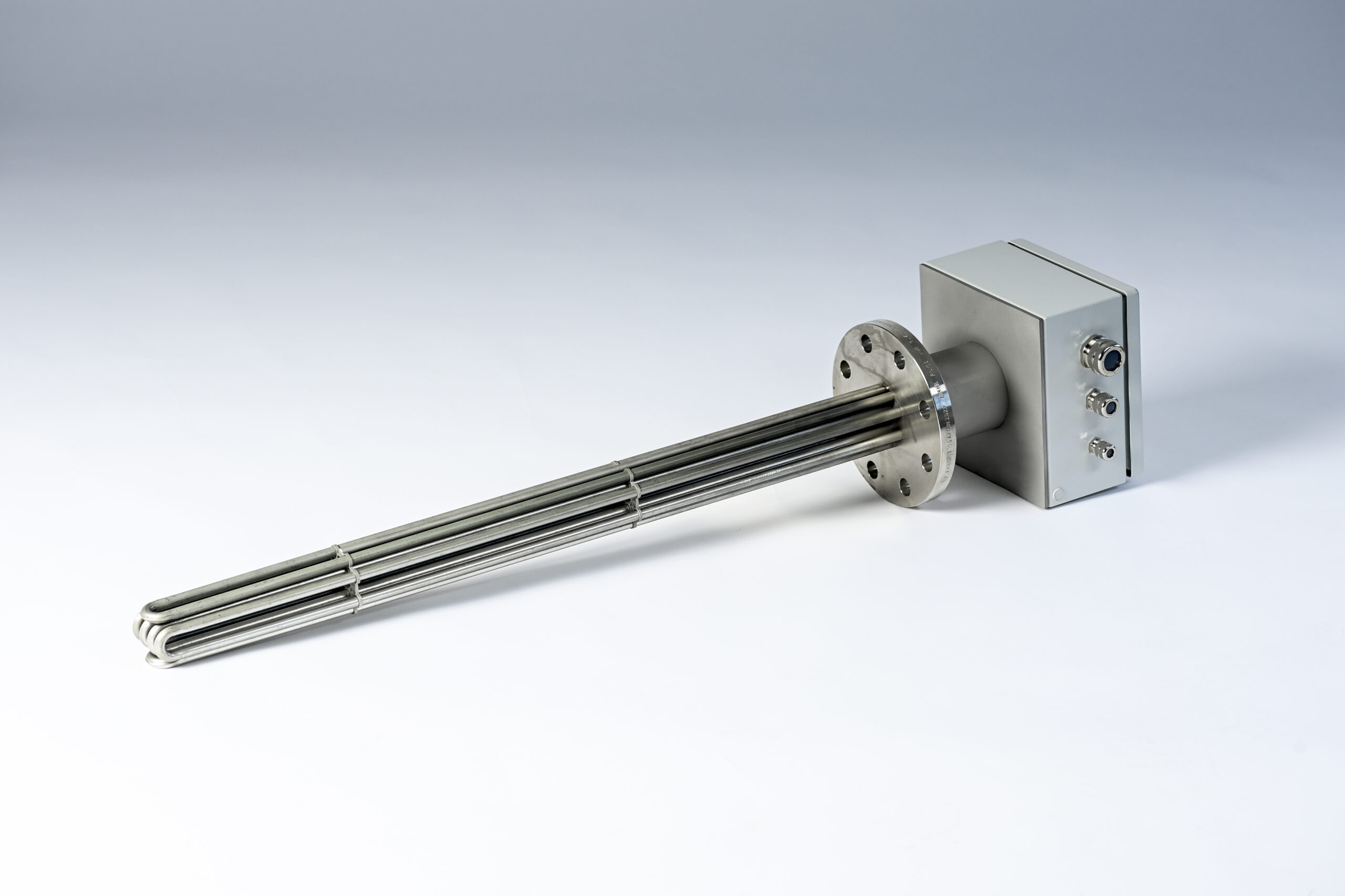

Electric flange heater

Refers to an electric heater that is mounted using a flange in a tank or another device to heat the medium to the required temperature. This is the “big brother” of the electric screw-in heater and can usually produce much higher thermal power. Siekerkotte builds these types up to the megawatt range and manufactures flange heaters to fit the customer’s requirements to the letter. To ensure fast delivery times, Siekerkotte has pre-assembled modular electric flange heaters up to 320 kW for heating water.

You have questions on the topic of heating technology?

If you have any further questions, please contact us directly, we are happy to help!

Mail Schreiben